Stem extensions:

Where the design of the customer’s XMT demands the need to overcome space envelope challenges we can help achieve their requirements. For example, where the small bore subsea valve is required to be placed deep within the XMT due to these space challenges, LB Bentley can design and build bespoke stem extensions that still enable ROV access to operate the valve in such a position, without compromising the reliability of the valve operations. This can all be achieved whilst ensuring the correct positions of earth straps, the consistency in electrical continuity and that the position of the valve is being correctly shown by means of a directly linked indicator.

Compensators:

Where necessary, we can provide purpose-designed hydraulic compensators. They seal directly onto the valve bonnet without the need for external pipework, providing a piston displacement function if a sea chest is not available, ensuring the integrity of the valve in deep water.

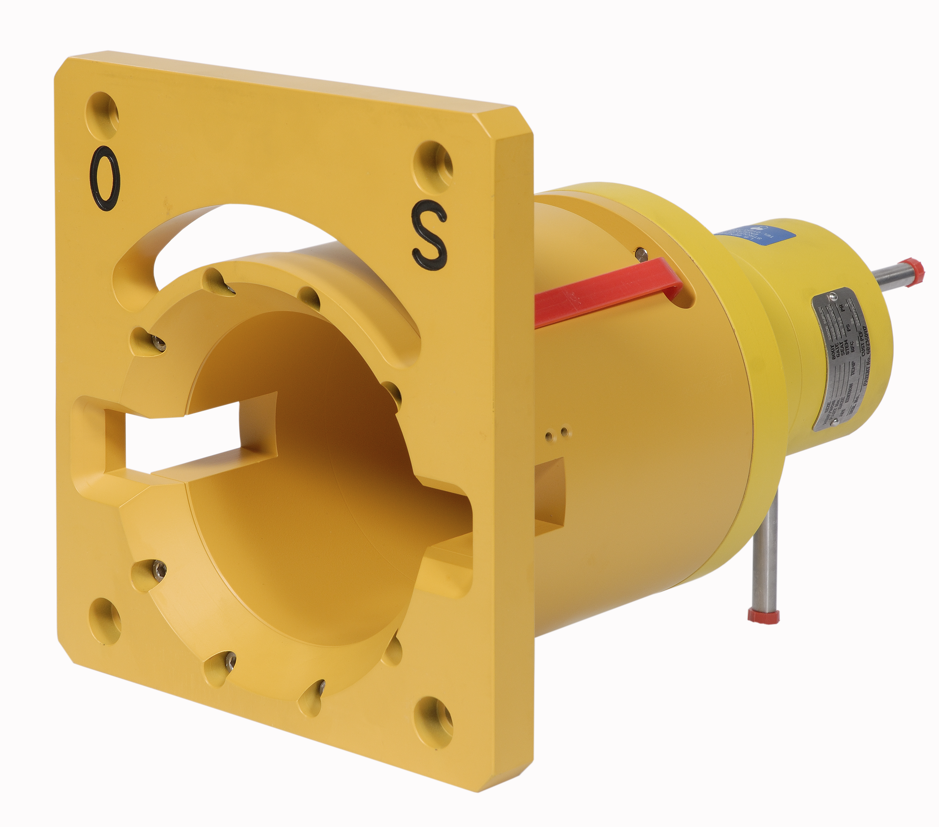

ROV (Remote Operated Vehicle) Recptacles/Buckets:

Where the valve is panel mounted or is operated by means of a stem extension ROV receptacles can be supplied in all the usual interfaces, for example, ISO 13628-8 Class 2, 3 and 4, High Torque/Low Torque or interfaces personalised to customers’ requirements or specifications. The ROV receptacles may be mounted to the valve, the actuator or the panel at the end of a stem extension, they may also be supplied as a stand-alone unit.

Despite many orders initially being “repeat”, we recognise that as technology and industry demands change, much of the “repeat” enquiries become bespoke to meet customers’ specific needs or requirements.

An in-house facility is also available to provide servicing, upgrading and re-testing of previously supplied LB Bentley products, no matter how old they are.